As the global nutraceutical industry increasingly prioritizes natural, evidence-based, and efficacious solutions, bioactive mushroom ingredients—such as Antrodia cinnamomea, Hericium erinaceus (Lion’s Mane), Cordyceps spp., and Inonotus obliquus (Chaga)—are drawing significant interest from B2B buyers and R&D stakeholders. These medicinal mushroom are valued for their diverse pharmacological activities, particularly their immunomodulatory, neuroprotective, and adaptogenic properties.

However, the method of production directly impacts active compound content, quality consistency, production cost, and application flexibility—making it a critical factor in material selection.

This article provides a comparative evaluation of two primary mushroom production technologies—conventional fruiting body cultivation (e.g., solid-state fermentation via bag or log culture) and advanced submerged mycelial fermentation. By examining their respective technical profiles, advantages, and limitations, we aim to provide a clear, science-based reference for professionals involved in sourcing, R&D, and functional product development.

1.

What Are Fruiting Bodies and Mycelium?

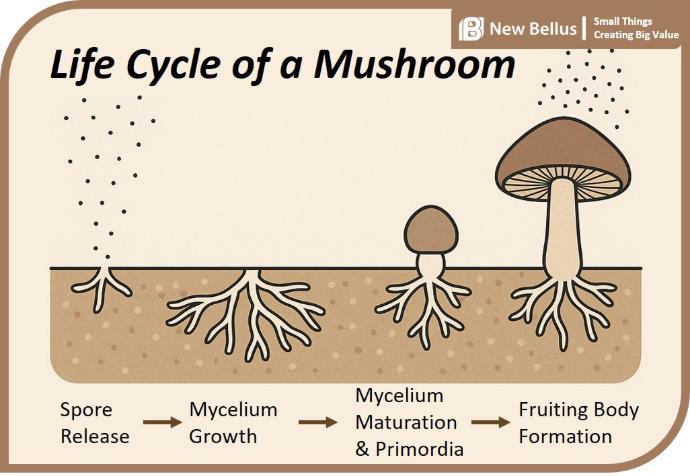

- Fruiting Body: The macroscopic, spore-producing reproductive structure of a mushroom, typically harvested at maturity. It is commonly cultivated using solid-state fermentation techniques such as bag culture or log inoculation.

-

Mycelium: The filamentous, vegetative growth form of

fungi, composed of hyphae. In industrial applications, mycelium is produced

efficiently and at scale through submerged liquid fermentation in bioreactors

under aseptic and controlled conditions.

Visual: Life Cycle of a Mushroom

2. Comparative Analysis of Production Methods

Fruiting

Body Cultivation

Traditional cultivationof mushroom fruiting bodies—referring to the macroscopic, spore-producing reproductive structures—is typically conducted via solid-state fermentation, such as bag or log cultivation. These methods rely on open externalenvironments and extended timelines to allow fruiting body formation. The advantage lies in their relatively simple process and low initial capital investment—making them accessible for small- to medium-scale agricultural producers.

While this method offers a relatively low barrier to entry and utilizes well-established protocols, it is limited by its dependence on environmental conditions (e.g., temperature, humidity, light cycles). This often leads to inter-batch variability in bioactive metabolite content and morphological characteristics. Moreover,. despite marketing claims emphasizing total polysaccharide content, fruiting body extracts are often dominated by α-glucan, a digestible polysaccharide with minimal immunomodulatory effects. This results in a mismatch between perceived efficacy and actual efficacy.

In terms of production efficiency, the entire growth-to-harvest process can take over 6 months, followed by post-harvest steps like drying and solvent extraction. These steps may involve thermal degradation of thermolabile bioactives, resulting in reduced potency. Furthermore, the risk of bioaccumulation of heavy metals and pesticide residues from the substrate poses quality and safety challenges. While fruiting body cultivation is easier to implement, its limitations in standardization and bioactive content quantification makes it difficult to meet today’s demand for verifiable, label-friendly, and quantifiable functional ingredients.

Submerged

Fermentation Mycelium

Submerged fermentation of mushroom mycelium represents an advanced biotechnological platform for producing bioactive compound-enriched mushroom. In this process, the filamentous vegetative hyphae of mushrooms—the mycelium—are cultured in nutrient-rich liquid media under sterile, controlled bioreactor conditions. Through optimized nutrient media and controlled environmental parameters, mycelium can be grown at scale in just 15–30 days, offering exceptional reproducibility and consistency—key priorities for functional food and supplement developers.

With precise fermentation control, manufacturers can induce and accumulate critical bioactives such as β-glucans, Erinacine A (from Lion’s Mane), and Cordycepin (from Cordyceps). These compounds have been scientifically validated for immune modulation, neuroprotection, and anti-inflammatory effects, and are qualitatively and quantitatively verifiable, meeting the market’s highest standards.

Unlike fruiting bodies, which are prone to contamination from pesticides and heavy metals, submerged fermented mycelium is cultivated in closed systems, free from environmental pollutants—resulting in superior purity and safety.

From an R&D standpoint, submerged fermentation allows customized process designs tailored to specific health benefits. Variables such as oxygen levels, pH, and nitrogen source can be adjusted to maximize compound biosynthesis, making this a highly flexible and future-ready platform.

Moreover,

mycelium produced through this method offers broad

formulation versatility, suitable for capsules, powders,

drinks, or liquid concentrates—empowering developers to innovate across

categories

Fruiting Body vs. Submerged Fermentation Mycelium: Summary Table

|

Category

|

Fruiting Body (Solid-State)

|

Submerged Fermentation Mycelium

|

|

Production

Cycle

|

6–36

months

|

15–30

days |

|

Active

Compound Stability |

Fluctuates —

based on external conditions

|

Stable —

optimized via submerged fermentation technology

|

|

Polysaccharide

Type

|

Often

high in α-glucans (less

functional)

|

Rich in β-glucans (proven immune-boosting effect)

|

|

Safety

|

Risk of

contaminants (e.g. heavy metals, pesticides)

|

High — clean, low-risk, no endotoxins

|

|

Consistency

|

Variable — influenced by environment

|

High — controlled growth conditions

|

|

Technical

Requirements

|

Low

(traditional agricultural practice)

|

High

(bioreactor & membrane filtration tech)

|

|

Production

Cost

|

Lower,

less complex processing |

Higher

upfront cost, advanced equipment needed

|

3.

Technical Advantages of NEW BELLUS Functional Mushroom

Mycelium

- Patented Submerged Fermentation: Submerged Fermentation with Biotransforming-tech™ to enhance β-glucan and other target actives.

- Patented Membrane Filtration System: Uses low temperature membrane filtration to preserve high-molecular-weight polysaccharides for improved bioavailability.

- Global Certifications: Includes FSSC 22000, HACCP, NSF GMP, HALAL, and ISO 17025—ensuring quality and export readiness.

- Multi-National Patents: NEW BELLUS® holds patents across multiple mushroom species such as Antrodia, Lion’s Mane, and Cordyceps.

- Comprehensive Safety Data: Key materials are backed by genotoxicity test, genotoxicity test, 28-day

subacute toxicity, and 90-day chronic toxicity test.

4.

Recommendations for B2B Procurement and Product Development

If

your business values:

- Large-scale, reliable sourcing

- Scientifically validated bioactivity

- Standardized, label-compliant ingredients

- Flexible formulation and application potential

Then submerged fermented mycelium is your most competitive and scalable solution.

NEW BELLUS® continues to invest in mushroom biotechnology and global collaboration to support partners in building the next generation of high-value health products.